Description

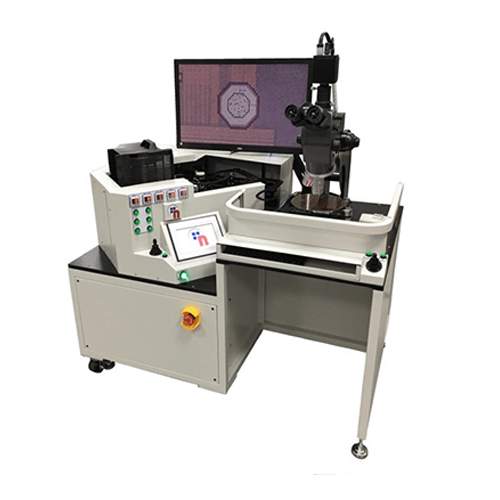

Description of this machine:

Wafer size

8-inch wafer (can be customized to meet other wafer sizes)

Wafer load/unload module

- Use Open cassette

- Mapping function of wafers, which can effectively detect wafers, wafers, oblique wafers, convex wafers, and stacked wafers (no warpage)

Aligner Module (Aligner)

- The center of the circle is automatically aligned, and the angle can be adjusted according to the Notch or the flat edge.

- It can do micron-level precise alignment for transparent or non-transparent sheets.

- The light source can be selected according to customer needs.

- For personnel to visually inspect the front, back, and back edges.

- The joystick can be adjusted manually, and the rotation angle can be adjusted arbitrarily. The inspection angle can also be set, and the angle can be automatically rotated and adjusted.

- Can do NG film records.

- The station can be selected and used according to the process.

- Can do simple manual measurement.

- The joystick can be manually controlled to move the stage to any position for inspection.

- The electric stage can set multi-point inspection points and perform automatic inspection.

- The software can record NG points with reproducibility.

- The station can be selected and used according to the process.

control element

PLC + HMI

Optional requirements ( Option )

- Warped sheet processing (<10mm)

- Wafer ID (OCR limited Semi standard font).